Real time detection

Assists in generating reports

Brand: High Sense Solutions Inc.

Made in: Canada

The IRX5000 Acoustic Infrared Two in One Imager is an advanced industrial device that integrates acoustic and infrared imaging technologies. This device is suitable for quantitative non-contact heat detection and imaging, with the ability to measure quickly, accurately, and repeatedly. It also supports defect detection and imaging based on sound waves. It is widely used in quality control, maintenance, and damage diagnosis in industries such as manufacturing, aerospace, wind power, and automobiles. In addition, the device has a highly intelligent feature and can perform various measurements and analyses through software control and data processing, making it very suitable for the needs of industrial automation and digital production.

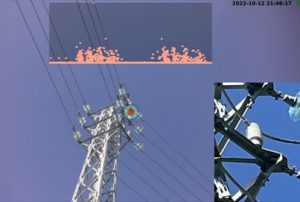

Real time visualization of partial discharge

Real time detection of partial discharge signals generated by equipment and conversion of the signals into visual images, intuitively reflecting the health status of the equipment.

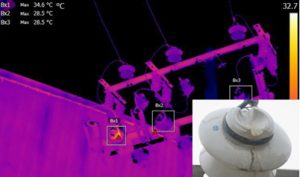

Partial discharge type judgment

By collecting partial discharge signals and analyzing them through various algorithms, the type of partial discharge can be determined

Traceability of testing site

Record the detection results one-to-one with photos, videos, and other information from the actual detection site. Users can quickly and accurately locate the fault source through the sound and image information saved on the device, and can replay the saved records at any time, facilitating subsequent analysis and processing by users.

Assist in generating detection reports

The auxiliary detection report generation function of the S860 acoustic imaging instrument can help users quickly and accurately generate a complete detection report, improving their work efficiency and the credibility of detection results